Facilities

- Home

- Facilities

- Aizu Factory

Features

- Contract manufacturing of tablets, oral jelly, and granules from formulation to packaging

- Prototyping and analytical evaluation for transition from the experimental stage to the actual production stage

- Process improvement in actual production

History

It has been in operation since 1985 in Aizu Wakamatsu City, about 120 km inland from the Pacific coast.

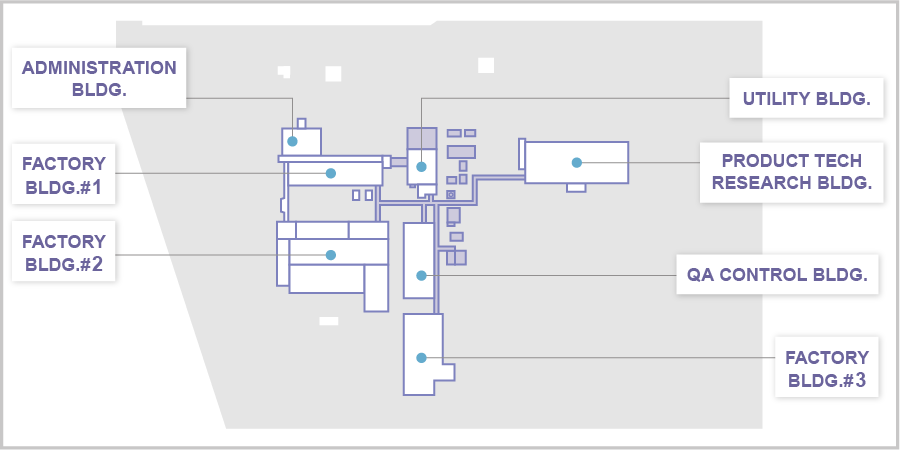

Scale and equipment

110,000 m², buildings with a total floor area of approx. 23,000 m² are located, mainly the 1st and 2nd plant buildings, the 3rd plant building, the quality control building, the production technology research building, and the administration building.

Layout

The 2nd plant buildings

Function

From formulation to packaging

- · Single-flavor tablets

- · Film-coated tablets

- · Core tablets and granules

System

Manufacturing engineering system (MES)

Three-dimensional automated warehouse management system

Gravity flow system

Eliminate human error and ensure efficient manufacturing

The highest pressure system in clean corridors to prevent contamination

constantly monitored temperature, humidity, and differential pressure between rooms by the environmental monitoring system (PERMS) to maintain cleanliness

The 3rd plant buildings

Function

Dedicated building for oral jelly products

A series of functions from jelly preparation to filling, sterilization, and packaging

System

Manufacturing engineering system (MES)

Three-dimensional automated warehouse management system

Eliminate human error and ensure efficient manufacturing

Production room

Clean corridor and maximum pressure system to prevent contaminatio

Constantly monitored temperature, humidity, and room pressure by Particle Measuring Systems (PMS) to maintain cleanliness

Process

Automated with the introduction of tray loading equipment and AGVs

Quality Control Building

Incoming testing of raw materials, quality analysis of manufacturing processes, and outgoing testing of products

Using the latest analytical equipment and advanced analytical techniques, physical and microbiological tests on solid preparations and oral jelly formulations

Analyzing foreign substances

Production Technology Research Building

Mainly of general area such as office

Formulation area

Analysis area

Function

Production transition from experimental to actual production machines

Pilot plant scale prototyping and evaluation for process improvement of products

Equipped with analytical instruments for physicochemical evaluation of APIs and a clean area for microbiological testing

CONTACT

As a company specializing in contract manufacturing of pharmaceutical drugs, we offer a wide range of contract services tailored to clients’ needs based on our extensive experience and know-how accumulated over many years.